Blogs

Seawater Intake & Outfall Dredging: Engineering Methods, Challenges & Specialist Solutions

Summary

This blog breaks down the fundamentals and advanced engineering considerations behind Seawater Intake and Outfall Dredging, a mission-critical scope for coastal infrastructure such as desalination plants, thermal power stations, fertilizer plants, and marine processing units. The content covers dredging methods, project challenges, environmental compliance, equipment selection, trenching workflows, risk mitigation, and how engineering-driven marine contractors like Rock & Reef deliver precise, reliable, and long-term solutions. The blog is designed to support decision-makers, EPC contractors, and marine planners who are evaluating partners for intake and outfall development.

Table of Contents

- Introduction

- What Is Seawater Intake & Outfall Dredging?

- Why This Scope Is Critical for Coastal Infrastructure

- Intake & Outfall Construction Workflow

- Dredging Techniques Used in Intake & Outfall Projects

- Equipment Selection: Backhoe, Cutter Suction, Grab & Trailing Suction

- Technical Challenges & How Specialists Solve Them

- Environmental & Regulatory Compliance

- Comparison Table: Intake vs Outfall Dredging Requirements

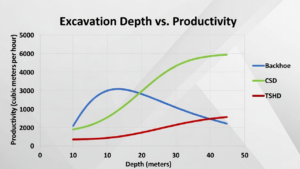

- Graph Insight: Depth vs Productivity Across Dredger Types

- Why Engaging a Specialist Marine Engineering Partner Matters

- Rock & Reef’s Dredging & Shipbuilding Capabilities

- Applications & Industries We Serve

- Final Thoughts + Call to Action

1. Introduction

Coastal industries rely on seawater as a lifeline, whether for cooling, processing, circulation, or discharge. Behind every stable operation lies one silent but essential activity: seawater intake and outfall dredging. When this work is engineered right, plants run smoothly for decades. When it’s not, operational downtime becomes unavoidable.

As a company deeply entrenched in dredging, trenching, shipbuilding, and marine engineering, Rock & Reef approaches intake and outfall development with a blend of traditional marine know-how and disciplined project execution.

2. What Is Seawater Intake & Outfall Dredging?

Seawater intake dredging involves forming precise underwater channels for pipelines that carry seawater into a plant. Outfall dredging involves creating pathways for discharge pipelines that release treated or cooled water back into the sea.

This scope demands:

- Accurate trench depth

- Stable seabed preparation

- Sediment control

- Precision at shallow & deep-water zones

- Controlled excavation near sensitive marine zones

It’s not standard dredging. It’s engineering dredging.

3. Why This Scope Is Critical for Coastal Infrastructure

A well-executed intake/outfall system ensures:

- Unrestricted seawater flow for operations

- Reduced siltation and pipeline blockage

- Maximized plant uptime

- Long-term structural stability

- Compliance with marine regulations

Industries depending heavily on this:

- Desalination plants

- Thermal power plants

- Oil & gas terminals

- Petrochemical units

- Marine processing plants

4. Intake & Outfall Construction Workflow

A specialist-led project typically follows this sequence:

- Hydrographic survey

- Geotechnical investigation (soil, rock, sediment)

- Pipeline route engineering

- Trench design & dredging method selection

- Controlled excavation with backhoe or CSD

- Pipeline laying, sinking & stabilization

- Backfilling & armoring

- Commissioning & final bathymetry reporting

Each phase impacts long-term performance, which is why contractor expertise is non-negotiable.

5. Dredging Techniques Used in Intake & Outfall Projects

a) Backhoe Dredging

Ideal for shallow depths, rocky seabeds, and precise trenching.

b) Cutter Suction Dredging (CSD)

Suitable for compact soils and large volume removal.

c) Grab Dredging

Used where selective excavation is needed—harbors, ports, restricted zones.

d) Trailing Suction Hopper Dredging (TSHD)

Effective for long-distance disposal and sandy seabeds.

6. Equipment Selection: What Fits Where

To give stakeholders clarity, here’s a simplified comparison:

| Dredger Type | Ideal Depth | Soil Type | Advantages |

| Backhoe Dredger | 0–25 m | Hard/rocky | High precision, trench accuracy |

| CSD | 2–30+ m | Medium to hard soil | Powerful cutting, productivity |

| Grab Dredger | 3–40 m | Mixed soils | Flexibility, controlled excavation |

| TSHD | 10–60+ m | Soft/sandy | Fast volume removal, long haul disposal |

7. Technical Challenges & How Specialists Solve Them

1. Working in High-Turbidity Zones

Solution: real-time dredging control, turbidity curtains, phased excavation.

2. Rock Layers Along Pipeline Route

Solution: rock-breaking attachments, controlled chiseling and underwater profiling.

3. Precise Depth Requirements

Solution: RTK/GPS positioning, multibeam surveys, and auto-monitoring systems.

4. Pipeline Stability During Installation

Solution: engineered bedding materials, weighted jackets, trench armoring.

5. Marine Traffic & Restricted Zones

Solution: navigation coordination, controlled work windows, safety zoning.

8. Environmental & Regulatory Compliance

Compliance is not optional. Key requirements include:

- Marine EIA

- Turbidity limits

- Disposal site approvals

- Sediment management

- Coral & habitat protection

- Post-work bathymetry & reporting

A disciplined contractor ensures these are met without slowing the project timeline.

9. Comparison Table: Intake vs Outfall Dredging Requirements

| Parameter | Intake Pipeline | Outfall Pipeline |

| Flow Direction | Seawater → Plant | Plant → Sea |

| Sensitivity | High sediment risk | High diffusion requirement |

| Depth Control | Very tight | Moderate |

| Trenching | Narrow & precise | Wider depending on diffuser length |

| Stabilization | Rock bedding | Concrete mattresses/ballast |

| Disposal Material | Often reused for backfill | Mostly offshore disposal |

10. Graph Insight: Depth vs Productivity

Key Takeaway:

Backhoes excel in precision at shallow depths, CSDs dominate productivity in mid-depths, and TSHDs outperform in deepwater bulk excavation.

11. Why Engaging a Specialist Marine Engineering Partner Matters

General contractors may handle volume digging, but intake/outfall work demands engineering-led dredging. A specialist like Rock & Reef brings:

- Purpose-built dredgers

- Experienced marine engineers

- Trenching & pipeline-laying capability

- In-house shipbuilding expertise

- Coastal and offshore project management discipline

This combination shortens project timelines and enhances long-term asset performance.

12. Rock & Reef’s Dredging & Shipbuilding Capabilities

Core Strengths:

- Backhoe dredgers for precision trenching

- Grab dredgers for selective removal

- Custom-built marine vessels

- Trenching & seabed preparation

- Pipeline installation support

- Breakwater & marine civil infrastructure works

- Offshore logistics & pontoon fabrication

“Engineering-driven dredging and shipbuilding solutions for India’s coastal infrastructure.”

13. Applications & Industries We Serve

- Desalination facilities

- Coastal power plants

- Oil & gas terminals

- Fertilizer & petrochemical plants

- Ports & harbors

- Marine EPC contractors

14. Final Thoughts + Call to Action

Seawater intake and outfall dredging isn’t routine excavation; it’s strategic engineering that protects the long-term performance of coastal industries. With the right partner, the entire asset lifecycle becomes efficient, reliable, and predictable.

If your organization is planning intake or outfall development, or exploring upgrades to existing systems, our marine engineers and dredging specialists are ready to advise, collaborate, and deliver end-to-end project support.

Let’s build your next coastal asset with confidence. Connect with Rock & Reef’s specialist team today.