Blogs

Desalination Plant Dredging: Technical Guide for Coastal Infrastructure, Seawater Intake & Outfall Systems

Summary

This pillar blog demystifies the entire lifecycle of Desalination Plant Dredging, backed by technical insights from real-world marine engineering operations. It walks stakeholders through intake channel dredging, diffuser outfall preparation, trenching, spoil management, turbidity control, environmental compliance, and long-term O&M requirements. The goal is to equip planners, consultants, and contractors with a clear, specialist-level perspective while positioning Rock and Reef as a reliable, execution-driven partner for desalination-linked dredging and marine construction across India.

Table of Contents

- Introduction

- Why Dredging Is the Backbone of Desalination Infrastructure

- Core Dredging Requirements in a Desalination Project

- 3.1 Intake Channel Dredging

- 3.2 Outfall Trench Dredging

- 3.3 Intake Structure & Foundation Preparation

- 3.4 Pipeline Corridor Dredging & Backfilling

- Types of Dredgers Needed for Desalination Works

- Technical Workflow: How a Desalination Dredging Campaign Is Executed

- Environmental & Regulatory Compliance

- Risk Factors & Mitigation Strategies

- Comparison Table: Intake vs Outfall Dredging Requirements

- Graph: Production Rates of Dredgers in Typical Desalination Sediments

- Why Desalination Plants Fail When Dredging Is Poorly Planned

- How Rock and Reef Supports Desalination EPCs End-to-End

- Final Recommendations for Project Owners

1. Introduction

Desalination plants are a strategic infrastructure. They demand precise coastal engineering, stable seabed conditions, and uninterrupted seawater intake.

And here’s the reality industry veterans know:

“The performance of a desalination plant is directly linked to the quality of dredging done during the intake and outfall development phase.”

Poor dredging = restricted flow, high sediment load, biological fouling, turbulence issues, and long-term O&M headaches.

This guide breaks down the complete dredging ecosystem behind desalination projects, practical, operational, and execution-ready.

2. Why Dredging Is the Backbone of Desalination Infrastructure

Every desalination plant depends on a stable, sediment-free intake channel and a carefully engineered outfall zone.

Key operational impacts:

- Ensures adequate seawater inflow

- Reduces pump strain

- Maintains constant Total Suspended Solids (TSS)

- Protects high-value filtration and RO components

- Ensures environmental compliance for brine discharge

Simply put, desalination without proper dredging is like a power plant without transmission lines; the system never reaches its operational potential.

3. Core Dredging Requirements in a Desalination Project

3.1 Intake Channel Dredging

Purpose:

- Create a stable pathway for seawater flow

- Achieve intake depth based on hydraulic modelling

- Remove soft silt, compact sand, or weathered rock

Technical Considerations:

- Required depth typically: -6m to -14m

- Target turbidity limits: 5–20 NTU, depending on region

- High-accuracy excavation is needed around intake screens

3.2 Outfall Trench Dredging

Purpose:

- Create a trench for the brine outfall diffuser pipelines

- Ensure controlled brine dispersion

Key Technical Points:

- Trench depth: 1.5m–4m below the existing seabed

- Gradient and slope are critical

- Outfall zones often have environmental restrictions

3.3 Intake Structure & Foundation Preparation

Tasks include:

- Rock dredging using BHD/CSD

- Micro-grading with grab dredgers

- Preparing stable bedding for intake wells

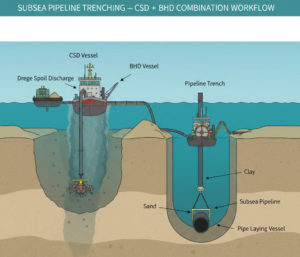

3.4 Pipeline Corridor Dredging & Backfilling

Usually executed using:

- Cutter Suction Dredgers (CSD) for continuous trenching

- Backhoe Dredgers (BHD) for precision

- TSHD for offshore sand sourcing

- Controlled backfilling to maintain pipeline integrity

4. Types of Dredgers Needed for Desalination Works

Cutter Suction Dredger (CSD)

- Best for compact sand, clay, light rock

- Ideal for intake and trenching corridors

Backhoe Dredger (BHD)

- High accuracy for intake zones & structures

- Works well in weathered rock

Grab/Clamshell Dredger

- Perfect for precision excavation around intake pits

Trailing Suction Hopper Dredger (TSHD)

- Used when offshore sand fill or large-volume transport is required

5. Technical Workflow: How a Desalination Dredging Campaign Is Executed

- Seabed Investigation (Bathymetry + Soil Report)

- Hydrographic Survey + Silt Spread Modelling

- Dredger Mobilization Plan

- Intake Channel Dredging

- Pipeline Corridor Trenching

- Backfilling with graded material

- Outfall diffuser trenching

- Rock trimming and bed preparation

- Environmental monitoring

- Post-dredging survey and verification

Each phase must align with turbidity targets, schedule milestones, and EPC commissioning timelines.

6. Environmental & Regulatory Compliance

Typical Mandates:

- Turbidity management

- Marine ecology protection

- Noise and vibration thresholds

- Disposal ground authorizations

- Bathymetric verification

- Coastal Regulation Zone (CRZ) approvals

Tools used:

- Silt curtains

- Silt screens

- Real-time turbidity sensors

- Anchor pattern optimization

7. Risk Factors & Mitigation Strategies

| Risk | Impact | Mitigation |

| Unexpected seabed rock | Schedule overrun | Pre-cutting + deploy BHD |

| High turbidity | Shutdown risk | Use silt curtains, adjust cutter speed |

| Weather downtime | Cost escalation | Seasonal scheduling |

| Pipeline floatation | Damage risk | Controlled backfilling |

| Sediment collapse | Rework | Trench stabilization |

8. Comparison Table: Intake vs Outfall Dredging Requirements

| Parameter | Intake Dredging | Outfall Dredging |

| Accuracy Required | Very High | High |

| Soil Type | Mixed/compact | Mostly soft to medium |

| Machinery | BHD + CSD | CSD + Grab |

| Environmental Sensitivity | Moderate | Very High |

| Depth Range | 6–14m | 3–10m |

| Special Needs | Intake screen protection | Diffuser slope control |

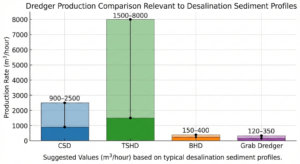

9. Graph: Production Rates of Dredgers in Typical Desalination Sediments

Suggested Values (m³/hour):

- CSD: 900–2500

- TSHD: 1500–8000

- BHD: 150–400

- Grab Dredger: 120–350

10. Why Desalination Plants Fail When Dredging Is Poorly Planned

- Reduced seawater intake due to siltation

- High pump wear and energy consumption

- Increased RO membrane fouling

- Brine discharge non-compliance

- Frequent shutdowns during monsoon sediment drift

- Escalating O&M costs

A desalination plant is only as good as the seabed engineering behind it.

11. How Rock and Reef Supports Desalination EPCs End-to-End

Rock and Reef offers an integrated, execution-led capability stack aligned with coastal desalination demands:

Core Marine Services

- Intake channel dredging

- Outfall Trenching

- Subsea pipeline trenching

- Controlled backfilling

- Rock dredging

- Capital & maintenance dredging

Engineering & Execution Strengths

- Multi-dredger fleet (CSD, BHD, Grab, Amphibious units)

- Hydrographic survey unit

- In-house fabrication & repair

- Marine project planning & risk management

- Coastal compliance experience

- Zero-compromise HSE protocols

12. Final Recommendations for Project Owners

For desalination plants, the most sustainable approach is early-stage collaboration.

Key Takeaways:

- Start dredging planning immediately after concept design

- Allocate budget for seabed surveys

- Select dredgers based on soil, not availability

- Plan trenching in alignment with pipeline installation windows

- Prioritize turbidity control to avoid regulatory bottlenecks

If you’re planning a desalination project intake, outfall or full marine civil package, Rock and Reef stands ready to deliver a dependable, execution-driven solution with the technical maturity your project deserves.